Menu

All in one

|

Weight

|

Lightweight

|

|

Assembly

|

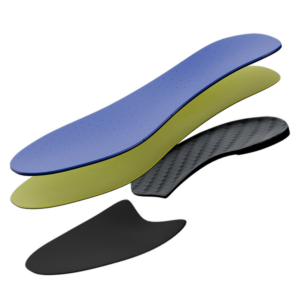

100% Carbon Made

|

|

Construction

|

Rigid

|

|

Heel Lift

|

3D-Printed, Removable

|

|

Top Cover

|

EVA, Double-colored, Perforated, double LAR-Midlayer

|

|

Front Part

|

EVA made

|

Ideal for:

- Use in daily training as well as for competition, in different sports (eg running, cycling, basketball, football, etc.)

HYBRID is our “multi-tool” orthotic model, as it can be effectively used during different sports, which they may require very different shoes, while at the same time preserves all the basic advantages of carbon construction. It enhances the forward movement of the foot and its stability in the shoe. The EVA made forefoot allows for a comfortable and easily adaptable fit, in different sports shoes (narrow Vs wide toe box, track shoes, cycling shoes, basketball/football boots, etc). The ultimate orthotic model for triathlon, under the “one size, fits all” logic.

Book a Consultation

Not sure of the orthotic model that will cover your needs in full, or you think that you should discuss special health issues plus other concerns, which may affect the choice of the specialised orthotic model? You can always schedule a meeting with us. We are always available to help you with one goal. Your complete satisfaction, from a fully customized and hassle-free application, which will take your sports experience to the next level and that will elevate your performance, with safety and comfort.

Materials & Methods

Ceramic Top Cover

- Strong ceramic print adds excellent wear resistance, preserves the cover color, and delivers outstanding anti-slip performance

Special channels in the coating design redirect moisture deep into the material, maintaining a dry and comfortable climate inside the shoe - In case the shoe becomes wet, maximum yet safe anti-slip properties are automatically activated

Foot stability inside the shoe, thereby preventing excessive and uncomfortable tightening of the laces - Enhances the ‘drive’ and ‘grip’ of sports shoes over time

- It offers unparalleled comfort during long-term use and prevents blackened nails, blisters, and calluses from forming

- It minimizes the unnecessary activity of the accessory foot muscles, thus improving running economy and preventing toe muscle cramps

- It protects against foot twisting (ankle sprain) inside the shoe and on technical terrain with extremely steep slopes (foot sprain).

LAR-Midlayer - “Reads” Athlete’s Needs

An innovative product of nanotechnology is embedded into every orthotic model we produce, placed between the orthotic shell and the ceramic upper cover. This midsole transforms the orthotic shell into a “living organism” that can adjust its properties by “reading” the athlete’s instantaneous needs.

- It changes its compressibility in response to variations in the rate or intensity of the compressive loads, a feature termed “Load Adaptive Response” (LAR)

Under mild exercise conditions, the LAR-Midlayer remains soft, ensuring the athlete enjoys a comfortable and restful experience - During intense activity, the LAR-Midlayer becomes rigid, unveiling the unique properties of the carbon orthotic shell, like bending, twisting, and compression stiffness, without any compromise

- It greatly mitigates the tissue vibration resonance phenomenon — responsible for neuromuscular fatigue which can lead to muscle cramping, tendinopathy, periostitis, and bone swelling

- It reduces the metabolic “debt” accrued during training, aiding in optimal musculoskeletal recovery between frequent training sessions

Orthotic Shell Design - Straight from the Future

An individual and unique mold is created after foot scanning. Using this mold, the orthotic shell is constructed, allowing for customization with millimeter precision to ensure a completely safe and ergonomic fit.

- Guided by AI, we employ a unique combination of weaving and overlapping techniques on the mold using pre-impregnated (with aerospace-standard resins) carbon, Kevlar, and nylon fabrics. These materials are then cured in an oven under vacuum pressure conditions

- Each orthotic shell exhibits diverse and case-specific properties in terms of rigidity and elasticity along different motion planes

- It reduces the rate of progressive deterioration of the sports shoe’s characteristics, especially during activities of extended duration or through cumulative use over time

- Our super lightweight construction offers unmatched durability. It doesn’t break, deform, and therefore never requires replacement

Innovative Orthotic Forefoot Design

The human foot is rich in nerves, blood vessels, and other sensitive tissues. That’s why the design of the front part of the orthosis is crucial for us; it shouldn’t merely aim to occupy space within the shoe. Through modifications to the 3D printing process, we have achieved two practically incompatible conditions. The anterior part of the orthotic insole enhances the construction’s performance (bending/torsion resistance, stability, and drive) while simultaneously providing comfort and safety to the sensitive tissues beneath the metatarsals.

- Progressive layering printing, which optimizes load distribution

Custom-curve formation in printing, facilitating the forward movement of the foot (drive) - AI-driven printing orientation allows for case-specific, mixed properties along different motion planes

- Intelligent cell network design in the broader area of the metatarsals (with varying geometric shapes for each case) enhances the construction’s bending and torsion resistance while maintaining elasticity in compression to protect the metatarsals from compressive forces

- Customized design suitable for use in various sports and on different terrains, including indoor halls, roads, and technical trails

Removable Parts - Fully Customized Experience

The rear, flat-bottomed heel lifter is printed with pre-defined specifications to guarantee an ergonomic and stable fit of the orthotic insole inside the shoe. Importantly, we have intentionally not permanently integrated this component into the orthotic shell to accommodate significant variables in the athlete’s daily life.

- It ensures an ideal orthotic fit in sports shoes with varying design characteristics, such as heel counters, shoe drops, midsole geometries, minimal designs, and inside volumes

- It facilitates the seamless synergy between the “custom orthotic-sports shoe” combination, catering to athletes with different movement patterns

- It optimally distributes compressive forces acting on the athlete’s foot and equalizes the loading on human tissues